PET washing line

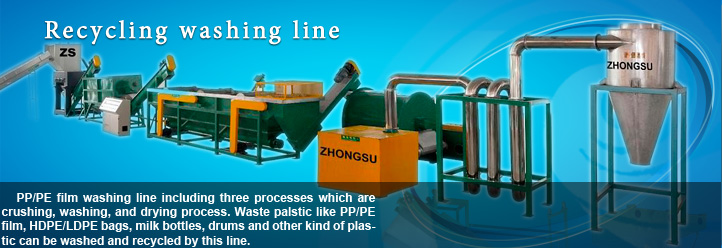

Our PET Washing Plants are high throughput, high performance recycling systems designed especially for post customer PET bottles with caps and labels from various sources. We offer different washing recycling system to our customers from different areas according to their individual requirements. The fianl purpose is to get the high purity ,low moisture ,uniformed clean PET flakes.

The whole system inclued the procedures: debaler, pre-washer, label remover, sorting, granulating, washing dewatering, second granulation for size reduction drying ect.

A typical PET bottle washing plant is consisit of the following components:• Belt conveyor: For waste material infeeding.

• Bale Breaker – opens the tight bales of PET bottles to loose bottles one by one.• Trommel screen: big trommel could separate heavy stones, caps, sand or other small contamination down from these bottles go through it.

• Pre-washing: This machine has a big volume should work with hot water with high temperature. It mainly used for pre-washing the bottles before crushing and removes some contamination out. ( PVC bottles after go through the hot water may change color and could be sorted out further.)• Label remover: For removing most percentage labels on the bottle body before crushing. This machine also have the function of pre-washing as well.

• Sorting belt: Sorting processed bottles again by manual to separate them by color ,type and sorting the dirties out before granulating.• Metal Detector – detects metal contamination that may remain in the bottles

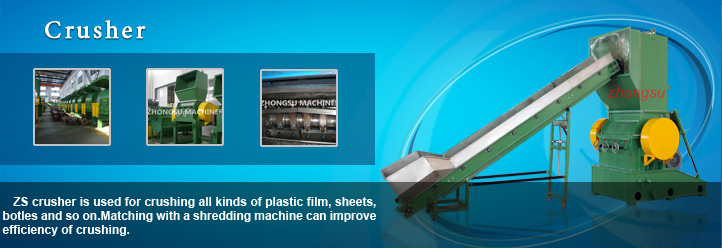

• Granulator/ Crusher: Wet crushing system.It used for material size reduction and pre-washing.• Screw conveyor : For PET flakes transportion

• High speed Friction washer( Scrub washing machine): High speed friction washing could achieve a good cleaning effects through the blades on the beating and spray. This machine is suitable for broken film and Plastic flakes washing.• Single screw or double screw washing tank/ Screw washer: For flakes floating washing and conveying.

• Hot Washing Tank/ steam washer – hot washing process with alkaline (caustic) soda to remove glue and oil• Horizontal dewatering machine( Dehydrator):This machine is mainly used for the cleaning of waste plastic after mechanical dewatering and drying, the spindle through high speed rotating threw the plastic and water to the screen, water releases by screen, while the plastic is from the outlet to be out of the machine enters into the next procedure. The machine has a good drying effect and high energy efficiency. The blade is made of high wear-resistant materials, can be replaced more conveniently.

• Second granulator (optional): For PET flakes size reduction to final size required.• Zig-Zag label separator: For separate labels in the crushed flakes.

• Blower and transition silo: transportation to storage silo.• Control cabinet: For control the whole system intensively.

output capacity : 500-600kg/h, 800-1000kg/h, 1000-1500kg/h, 1500-2000kg/h, 2000-2500kg/h, 2500-3000kg/h.After discussint with our customers, We can provide effective, customized proposals and turn-key solutions by listening to and understanding our customers’ needs.

Customers are warmly welcomed and encouraged to visit our factory to check some machines in operation.

Any more detailes you need, please feel free to contact with us.